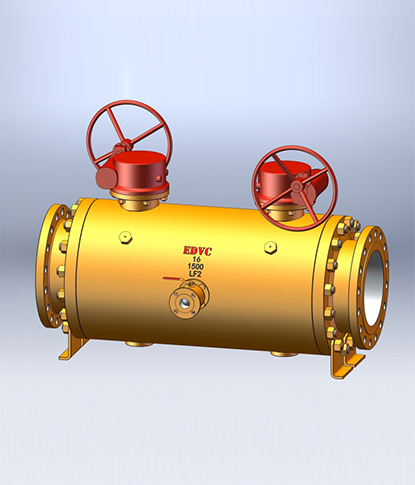

Double Block & Bleed Ball Valve

Designed for Critical, Zero-Leakage Isolation in High-Risk Applications

Our Double Block and Bleed (DBB) ball valves are designed to provide the highest level of safety and process integrity for critical pipeline and vessel isolation. By integrating two independent sealing barriers and a dedicated bleed port into a single compact unit, DBB valves provide verifiable isolation capabilities, enabling safe maintenance, pressure testing, and intervention operations. This design is an ideal solution for applications where operational safety, environmental protection, and asset integrity are paramount.

Engineered with Dual-Seal Redundancy and Verifiable Safety

A double block and bleed valve (DBB valve) features two independent primary sealing surfaces (seats) and a dedicated vent (or drain) port. When the valve is closed, it provides two reliable isolation barriers, blocking pressure from both the upstream and downstream sides, while simultaneously allowing the pressure in the central cavity to be safely vented to atmospheric or flare pressure through the dedicated port. This triple-seal system creates a verifiable zero-leak barrier, enabling operators to confidently isolate, vent, and test sections of piping, thus allowing for safe maintenance, pigging operations, or instrument calibration.

Delivering Enhanced Safety and Operational Confidence

Choosing a Double Block and Bleed (DBB) valve means investing in a proven method to significantly reduce risks during pipeline maintenance. Its integrated design eliminates the need for multiple valves, gaskets, or blind flanges, simplifying the piping system, reducing potential leak points, and lowering installation and lifecycle costs. The ability to vent and monitor valve cavity pressure provides reliable evidence of seal integrity, enhancing Lockout/Tagout (LOTO) procedures and ensuring compliance with stringent industry safety standards. This operational reliability protects personnel, the environment, and valuable assets.

Built for the Most Demanding High-Stakes Applications

Our DBB ball valves are indispensable components in critical applications within the energy and process industries. They are standard for main line shut-off valves, manifold systems, pig launcher/receiver station isolation, instrument root valve isolation, and any process where double isolation and bleed functionality are required for safety or ease of maintenance. These valves are widely used in oil and gas production, transportation, refining, chemical processing, and offshore platforms, where reliable isolation performance is crucial.

Engineered to Exceed Industry Standards for Performance and Safety

Our double block and bleed (DBB) valves are available in both floating and trunnion designs and comply with API 6D, ASME B16.34, and ISO 17292 standards, with fire-safe options available to API 607 standards. All valves are rigorously tested to ensure bubble-tight sealing at both the seat and vent. These valves are available in full bore or reduced bore designs and with a variety of materials and trim options, allowing for customization to specific needs and suitability for a wide range of media, from natural gas and crude oil to corrosive chemicals and high-pressure steam.

The Verified Choice for Secure Isolation

When your process requires verifiable, leak-proof isolation, standard single-seat ball valves are insufficient. Our double block and bleed ball valves (DBB ball valves) provide the redundancy, functionality, and reliability needed for safe operation in critical systems. They represent the highest standard in isolation technology, offering peace of mind through meticulously designed safety and reliability.

Previous: There is no more.