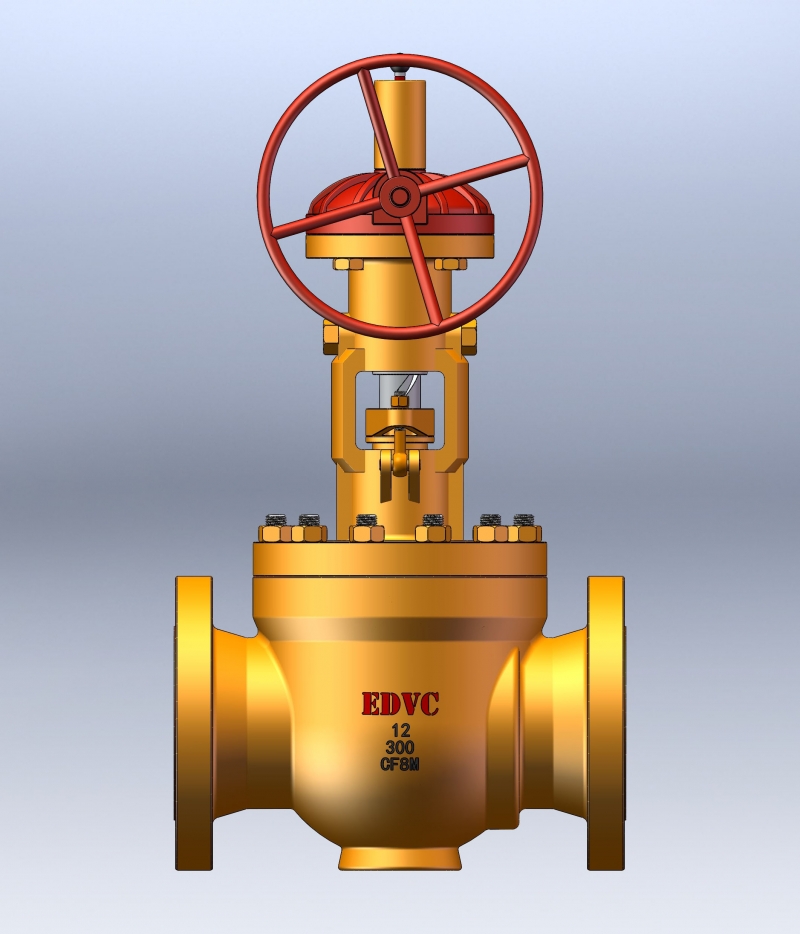

Rising Stem Ball Valve

Designed for Superior Sealing and Extended Service Life

Our Rising Stem Ball Valve are meticulously designed for zero-friction operation and exceptional service life, making them particularly suitable for high-cycle, high-temperature, or demanding applications. Unlike traditional ball valves (where the ball rotates against the seat, causing wear), the lift-type ball valve design eliminates sliding contact between the ball and the seat, providing unparalleled reliability and performance. This innovative design effectively prevents the wear problems common in traditional ball, gate, and plug valves, making it ideal for demanding applications requiring frequent opening and closing and zero leakage.

Engineered with Advanced Friction-Free Technology

The rising stem ball valve utilizes a unique inclined rotating mechanism to ensure friction-free operation. When the valve opens, the valve stem simultaneously rises and rotates, lifting the ball away from the valve seat, resulting in a friction-free process. When closing, the ball rotates and mechanically wedges into the valve seat, creating a gas-tight seal and ensuring zero leakage under harsh conditions. Made entirely of metal, this valve is fire-safe and operates reliably in extreme temperatures ranging from -196°C to +538°C. It can handle media containing particulate matter such as sand and short fibers and complies with NACE corrosion resistance standards, ensuring resistance to sulfide stress corrosion cracking in harsh environments.

Delivering Unmatched Performance and Reliability

Our rising stem ball valves deliver exceptional performance under a wide range of operating conditions. This series of valves is available in sizes ranging from NPS 2 inches to 24 inches (DN 50-600), with pressure ratings from Class 150 to Class 2500 LB (PN 10-420). The operating temperature range is from -60°C to +538°C, making them suitable for both low and high-temperature applications. The valve body is constructed from carbon steel, stainless steel, or alloy steel, while the ball and stem are made from high-performance materials, offering excellent corrosion resistance and mechanical strength.

Built for Critical Industrial Applications

Rising stem ball valves are indispensable critical components in industries where reliability and safety are paramount. They are widely used in oil and gas pipelines, petrochemical plants, power generation facilities, and water treatment systems. These valves are particularly suitable for applications such as venting, fluid transfer, pipeline isolation, bypassing, product segregation, and emergency shutdown, especially in situations requiring high switching frequency and zero leakage at high temperatures. Their fire-safe design, compliant with API 607 standards, ensures continued operation even in emergency situations.

Manufactured to Rigorous International Standards

Our lift-type ball valves are manufactured in strict accordance with API 6D, ASME and ISO standards. Each valve undergoes comprehensive testing to meet API and ISO standards, ensuring leak-tight sealing and long-term reliability. The anti-static design and blow-out proof stem structure provide additional safety features, while the extended stem option and multiple actuation methods (manual, pneumatic, electric) offer flexibility for various operating requirements.

Previous: There is no more.

Next: Orbit Ball Valve