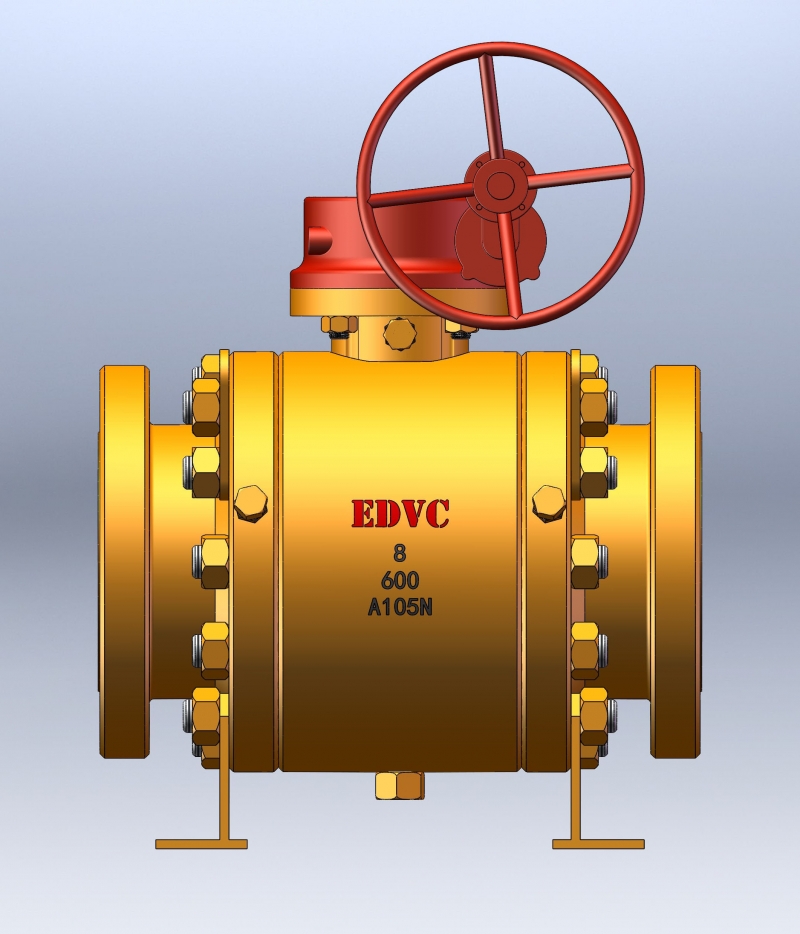

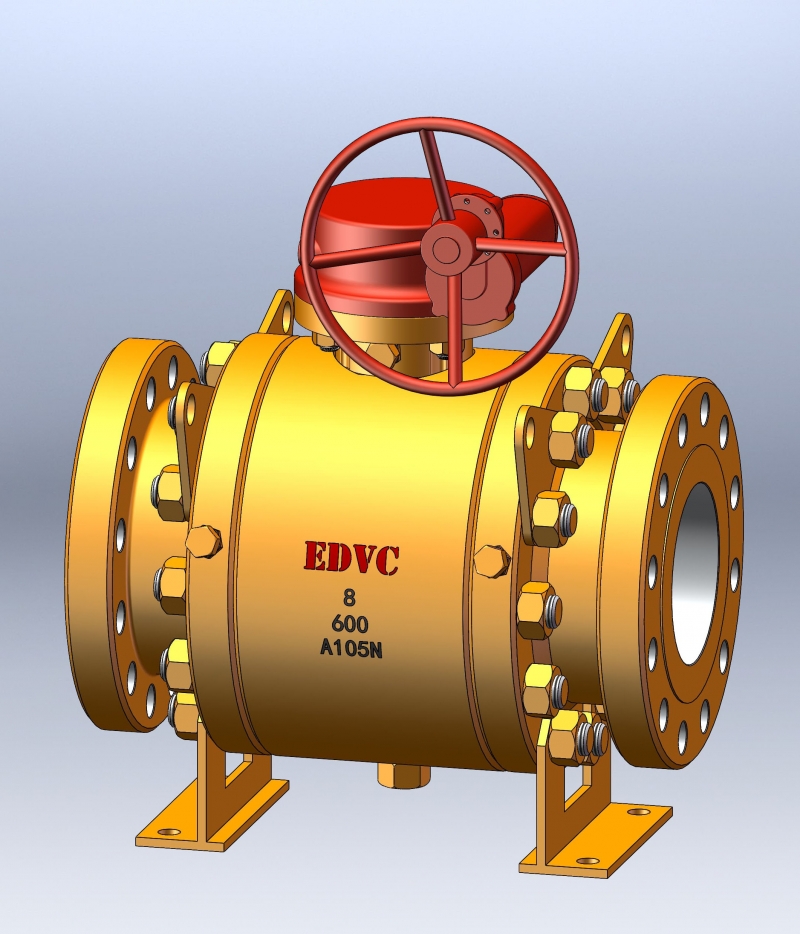

Trunnion Mounted Ball Valve

Designed for Superior Stability and Reliability

Our trunnion-mounted ball valves are designed for high-pressure, high-temperature applications where reliability and safety are paramount. Unlike floating ball valves, where the ball is free to move, trunnion-mounted ball valves feature a fixed ball design, securely supported by upper and lower trunnions. This innovative structure prevents axial floating and unwanted movement of the ball during operation, ensuring stable sealing performance even under extreme pressure conditions. Designed to withstand demanding industrial environments, this valve is ideal for critical industries such as oil and gas, petrochemicals, and power generation.

Engineered with Advanced Trunnion Technology

The core of our trunnion-mounted ball valve design lies in its fixed ball structure, where the ball is supported by trunnions at the top and bottom. This design transfers the fluid pressure forces to the bearings instead of the valve seat, significantly reducing seat deformation and ensuring stable sealing performance. The spring-loaded seat mechanism maintains continuous contact with the ball, providing bidirectional sealing capability even under low differential pressure conditions. The valve utilizes pressure-driven stem packing and is equipped with a pressure energizing ring. When the medium pressure acts on the ring, it generates an upward compressive force on the packing, ensuring reliable sealing even if the main O-ring is damaged.

Delivering Unmatched Performance and Reliability

Our trunnion-mounted ball valves deliver exceptional performance under a wide range of operating conditions. This series of valves is available in sizes ranging from 6 inch (DN150) and larger, with pressure ratings from Class 600 LB and above. The operating temperature range is from -196°C to 550°C, making them suitable for both cryogenic and high-temperature applications. The valve bodies are constructed from carbon steel, stainless steel, duplex stainless steel, or alloy steel, and are available in full bore or reduced bore configurations to meet different flow requirements.

Built for Critical Industrial Applications

Trunnion Mounted ball valves are indispensable critical components in industries where reliability and safety are paramount. They are widely used in oil and gas pipelines, petrochemical processing plants, power generation facilities, and chemical production. These valves are particularly suitable for applications requiring zero leakage and reliable shut-off, such as high-pressure gas transmission, crude oil pipelines, liquefied natural gas receiving terminals, and refinery feedstock lines. Their fire-safe design, compliant with API 607 standards, ensures continued operation even in emergency situations.

Manufactured to Rigorous International Standards

Our trunnion-mounted ball valves are manufactured strictly in accordance with API 6D, ASME B16.34, ISO, and BS6364 standards. Each valve undergoes comprehensive testing to meet API and ISO standards, including hydrostatic body testing and bidirectional seat testing at 1.5 times the maximum working pressure. The anti-static design and blow-out proof stem construction provide additional safety features.

Previous: There is no more.

Next: Side Entry Ball Valve