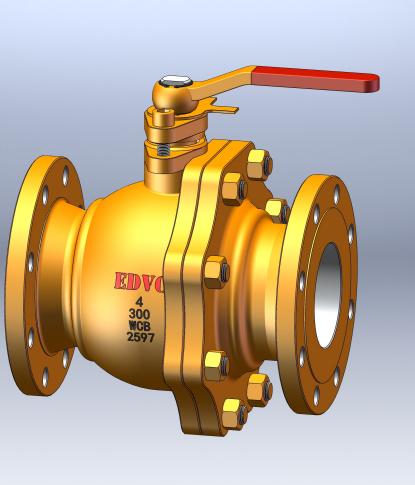

Floating Ball Valve

Designed for Cost-Effective Performance in General Service

Our floating ball valves are expertly designed to provide reliable sealing performance and convenient operation in a wide range of industrial applications. These valves feature a simple yet efficient design where the ball moves freely within the valve body, forming a tight seal against the downstream seat when closed. This simple mechanical structure makes floating ball valves an economical choice for standard flow control applications, while also meeting the requirements for high performance and long service life.

Engineered with Simple, Effective Sealing Technology

A key feature of floating ball valves is their simple design—the ball is not mechanically fixed but "floats" between the valve seats. When the valve is closed, the pipeline pressure pushes the ball against the downstream seat, creating a tight and reliable seal. This pressure-assisted sealing mechanism ensures reliable performance under various operating conditions. PTFE or reinforced PTFE valve seats offer excellent chemical resistance and low friction characteristics, while chrome-plated or stainless steel balls ensure smooth rotation and a long service life.

Delivering Easy Operation and Low Maintenance

Floating ball valves are designed for quick quarter-turn operation, making them easy to operate manually or control with compact actuators. Low operating torque and a simple design result in minimal maintenance requirements and extended maintenance intervals. The one-piece or two-piece body construction provides a robust pressure boundary, while the top or side entry design allows for easy access to internal components when maintenance is required. These features make floating ball valves ideal for applications where reliability and ease of use are paramount.

Built for Diverse Industrial Applications

Our floating ball valves are suitable for a wide range of applications, including water treatment systems, oil and gas pipelines, chemical plants, and industrial utility systems. These valves are available in sizes ranging from 1/2 inch to 12 inches (DN15-DN300), with pressure ratings from Class 150 to Class 2500, and can withstand temperatures from -196°C to 200°C. They are compatible with various media, including water, oil, gas, steam, and mildly corrosive chemicals, making them ideal for general industrial applications.

Equipped with Essential Safety Features

Each floating ball valve is equipped with standard safety features, such as a blow-out proof stem design to prevent the stem from ejecting under high pressure; a fire-safe design (optional); and an anti-static device for handling flammable media. Full-bore or reduced-bore design options meet different flow requirements, while flanged, threaded, or socket-weld end connections ensure secure installation in various piping systems.

Manufactured to International Standards

Our floating ball valves are manufactured according to API, ASME, and ISO standards, ensuring product quality and reliability. These valves prioritize cost-effectiveness and performance, offering an excellent balance of quality and value for standard industrial applications.

Previous: There is no more.

Next: API Unibody Ball Valve NPT Stainless Steel Floating Ball Valve