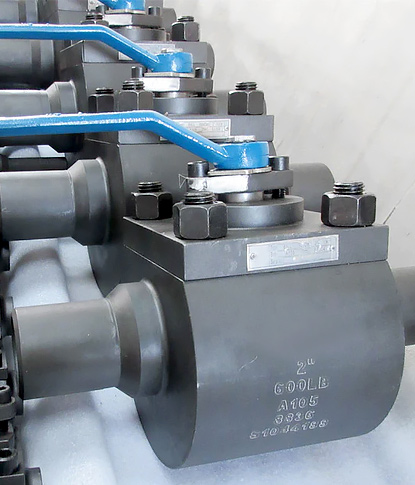

Forged Steel Top Entry Ball Valves

Designed for Easy Maintenance and Reliable Operation

Our forged steel top-entry ball valves are designed for demanding industrial applications, offering superior performance and convenient maintenance. The top-entry design allows all internal components to be inspected and maintained without removing the valve from the pipeline, making it ideal for applications requiring frequent maintenance or where valve removal is difficult due to space constraints. This innovative design features a one-piece forged steel body, providing exceptional strength and durability, ensuring reliable operation even under high pressure and high temperature conditions.

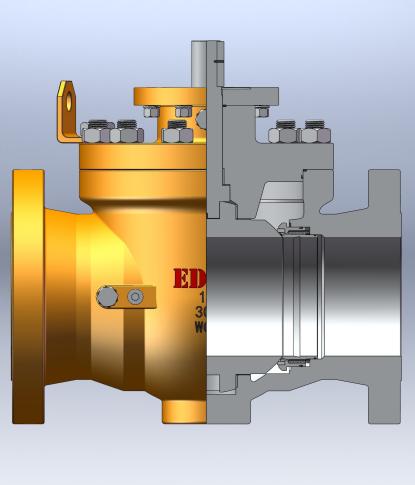

Engineered with Advanced Top Entry Technology

The core of our forged steel top-entry ball valve lies in its unique top-entry design. All internal components—including the ball, seat retainer, and stem—can be easily removed by loosening the bonnet, allowing for quick inspection, repair, or replacement while the valve remains in the pipeline. The trunnion-mounted ball design ensures precise positioning and reduces operating torque, while the spring-loaded seat mechanism provides bidirectional sealing capability. The valve features pressure-driven stem packing and is equipped with a pressure energizing ring that generates upward compressive force when subjected to media pressure, ensuring reliable sealing even if the main O-ring is damaged.

Delivering Unmatched Performance and Reliability

Our forged steel top-entry ball valves deliver exceptional performance under a wide range of operating conditions. This series of valves is available in sizes ranging from 2 inch to 60 inches (DN60 to DN1500) and pressure ratings from Class 150 to Class 2500 LB (PN16 to PN420). The operating temperature range is from -46°C to 121°C, making them suitable for both cryogenic and high-temperature applications. The valve bodies are constructed from forged carbon steel, stainless steel, duplex steel, or alloy steel, and are available in full bore or reduced bore configurations to meet various flow requirements.

Built for Critical Industrial Applications

Forged steel top-entry ball valves are indispensable critical components in industries where reliability and ease of maintenance are paramount. They are widely used in applications such as oil and gas pipelines, petrochemical processing plants, power generation facilities, and chemical production. These valves are particularly suitable for applications such as main line isolation, pipeline transportation systems, compressor stations, and metering stations, where in-line maintenance capabilities are crucial for minimizing downtime and operating costs.

Manufactured to Rigorous International Standards

Our forged steel top-entry ball valves are manufactured in strict accordance with API 6D, ASME B16.34 and ISOstandards. Each valve undergoes comprehensive testing to meet API and ISO standards, including hydrostatic shell testing and bidirectional seat testing at 1.5 times the maximum working pressure. Fire-safe design conforming to API 607 standard ensures continued operation even in emergency situations. Anti-static design and blow-out proof stem construction provide additional safety, while the double block and bleed (DBB) configuration ensures reliable isolation in high-risk scenarios.

Previous: Top Entry Trunnion Ball Valve

Next: There is no more.